Highlands College

Highlands College is home to all Montana Tech career-ready and transfer programs that help build the workforce we need in Butte and Montana.

From certificates and associate degrees to community education and customized training, Highlands offers you today’s relevant hands-on professional programs leading to tomorrow's important jobs. We continue to pursue industry-specific partnerships locally, giving you even more opportunities for employment.

At Highlands, you can complete a degree designed to help you enter the workforce immediately or earn credits for transfer into a four-year degree program. Regardless of your motivation, you’ll benefit from focused, skills-based instruction with profession-tested faculty, dedicated and helpful staff, and exceptionally affordable tuition.

Consider Highlands and transform not just your future, but our future.

2022 Graduates Surveyed

Our Altitude Isn't Nearly as Breathtaking as Your Potential

Let's find out together. Schedule a visit or call us at 406-496-4791 to see if Montana Tech is the place you should be.

If you want a great start before transferring to a four-year degree program at Montana Tech, the Associate of Science (AS) Degree is designed for you as a two-year program.

If you love to work with your hands and have a mind to solve problems, a career as an automotive technician may be for you.

Civil Engineering Tech graduates assist professional engineers with projects ranging from transportation, to sewer and water supply, to environmental solutions.

Students are prepared for construction industry careers through course work, service-learning projects, and through community service.

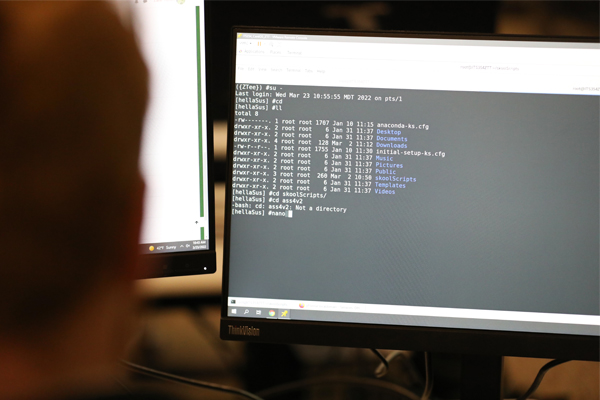

You'll be prepared for a variety of in-demand Information Technology careers by earning Montana Tech's Computer Networks and Cybersecurity A.A.S.

As a high school student, you can learn valuable college credit through our Big Sky Pathways and by taking college coursework today.

Students are prepared to work in an environment constructing projects such as utility trailers, pipelines, manufacturing, and industrial construction.

This one-semester certificate program prepares students for groundman and apprentice positions within the line trade.

Train for a career as a machinist with talented instructors and industry-leading tools.

A career in radiologic technology can lead in many directions, and there is strong demand for work.

Earn a two-year AAS degree and acquire marketable skills in web development and administration.

Welding is a high-tech industry that can take you all over the world.

Using a comprehensive curriculum, students in the Commercial Driver's License (CDL) program at Highlands College will receive online and classroom instruction and real behind-the-wheel driving experience on the skills course, within city limits and on both area highways and interstates.

The program provides students with the basic information and skills needed to provide care to residents/patients in assisted living/long-term care facilities and acute care settings. Individuals who complete the CNA course are eligible to apply for certification through the Montana Department of Public Health & Human Services after completing the Certified Nurse assistant graduation requirements.

Highlands College offers a six-month, rapid training in welding and machining in a hybrid format for veterans, active members of the National Guard, military Reservists, servicemen and women preparing to leave service, and spouses as part of a partnership with Operation Next and the nonprofit NFAMI.